PENGELOLAAN LINGKUNGAN INDUSTRI BERBASIS EKO-EFISIENSI DI KAWASAN SIMONGAN KOTA SEMARANG (An Ecological–Efficiency-based for Industrial Management in Simongan Areas, Semarang City)

Zaenuri Zaenuri(1*), Sudarmadji Sudarmadji(2), Chafid Fandeli(3), HA Sudibyakto(4)

(1) Fakultas MIPA Universitas Negeri Semarang

(2) Fakultas Geografi UGM Yogyakarta

(3) Fakultas Kehutanan UGM Yogyakarta

(4) Fakultas Geografi UGM Yogyakarta

(*) Corresponding Author

Abstract

ABSTRAK

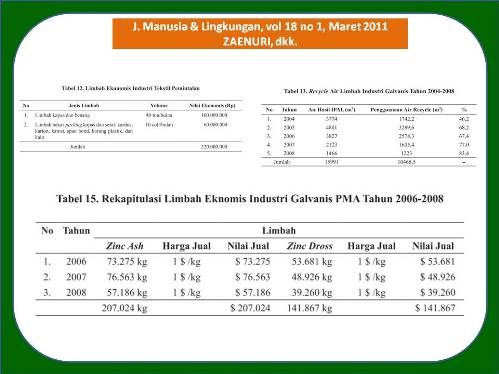

Penelitian ini bertujuan nntuk menganalisis bentuk-bentuk eko-efisiensi, serta keterkaitannya dengan pengelolaan lingkungan. Data yang diperoleh dianalisis secara deskriptif-komparatif. Hasil penelitian menunjukkan, bentuk eko-efisiensi yang dilakukan industri galvanis adalah recycle air limbah yang dihasilkan. Industri galvanis PMDN telah berhasil mendaur-ulang seluruh air limbah yang dihasilkan, sedangkan industri galvanis PMA berhasil mendaur-ulang sebanyak 1.742,2 m 3 atau 46,2 % air limbah yang dihasilkan pada tahun 2004 hingga mencapai 83,4% pada tahun 2008. Di samping itu, industri galvanis PMA telah berhasil mengelola limbah yang bernilai ekonomis, yakni zinc ash dan zinc dross selama kurun waktu 2006-2008, senilai Rp 3.488.910.000,00. Industri farmasi melakukan eko-efisiensi melalui program penghematan air, pemanfaatan kertas bekas untuk amplop gaji pegawai (reuse), penggunaan e-mail, dan pengelolaan barang bekas/limbah nonB3. Pemakaian air awal sebelum program penghematan rata-rata perbulan ± 10.000 m 3 (tahun 2000). Pemakaian air setelah program penghematan rata-rata perbulan ± 4.250 m 3 (tahun 2008) atau turun 57,5 %. Rata-rata penggunaan e-mail perbulan ± 2.500 email per bulan. Rata-rata penjualan barang bekas/ limbah nonB3 yang masih bernilai ekonomis (karton, plastik bekas, dll) ± Rp 5.750.000,00 perbulan. Industri furniture menghasilkan limbah yang bernilai ekonomis, seperti serpihan kayu, serbuk gergaji, dan sisa potongan kayu. Setiap hari rata-rata dihasilkan 30 m 3 serpihan kayu, 12 m 3 serbuk gergaji, dan 7 m 3 sisa potongan kayu. Di samping itu, dihasilkan sisa karton dan gabus rata-rata 2 m 3 per hari. Industri tekstil pemintalan menghasilkan limbah kapas dan benang, serta limbah bekas packing kapas dan serat, masing-masing 40 ton dan 10 colt perbulan, dengan nilai Rp 220.000.000,00. Dengan melakukan eko-efisiensi perusahaan telah melakukan pengelolaan lingkungan (aspek ekologi) untuk meraih efisiensi penggunaan sumberdaya (aspek ekonomi).

ABSTRACT

Objective of the research was to analyse several forms of ecological efficiencies and their relevancies to environmental management. The data were analyzed descriptively and comparatively. The analyses showed that one of the ecological efficiencies generated by galvanic industry was in the form of liquid-waste recycling. The PMDN galvanic industry had been able to successfully recycle all of its liquid wastes. Meanwhile, the PMA galvanic industry had been able to recycle 1,742.20M3 of its liquid wastes (or 46.2% of the total amount of the wastes) in 2004, increasing to reach 83.4% in 2008. In addition, during the period of 2006-2008, the PMA galvanic industry had been able to convert two of its liquid wastes, namely zinc ashes and zinc dross, to products with an economic value amounting to Rp. 3,488,900,000.00. The pharmaceutical industry generated ecological efficiencies through the reduction of the quantities of water consumed, reusing used papers for envelopes, e-mailing programs and reprocessing non-B3 waste products. In 2000, before the saving program for water uses was implemented, the average quantity of water consumed by this industry reached ± 10,000 m3 per month. In 2008, after the saving program for water uses was implemented, the average quantity of water consumed by this industry totaled only ± 4,250 m3 per month, or a reduction of 57.5%. The average uses of e-mails were ±2,500 per month and the average sales of non-B3 wastes (cartoons, plastics, and the like) were Rp. 5,750,000.00 per month. The furniture industry also generated economic wastes such as wooden plates, saw dust and small chopped wooden materials. On the average, 30 m3, 12 m3 and 7 m3 of wooden plates, saw dust and small-chopped wooden materials, respectively, were produced every day. Used cartoons and bubbles amounting to 2 m3 per day were also produced. The textile industry produced cotton & nylon wastes (40 tons per month) and wastes from cotton packages (10 wagons per month) with an economic value totaled Rp. 220,000,000.00. By implementing ecology-efficiency programs (ecological aspect), the company had been able to manage the environmental aspect quite well for reaching efficiency in the use of human sources (economic aspect)

Full Text:

Artikel lengkap (PDF) (Bahasa Indonesia)Article Metrics

Refbacks

- There are currently no refbacks.

Copyright (c) 2017 Jurnal Manusia dan Lingkungan